Dog Bone / Belt Type Expansion Joints

Dog Bone / Belt Type Expansion Joints – Complete Guide

Expansion Joints are essential components in modern industrial systems, ensuring smooth operations by managing thermal expansion, vibrations, and misalignments in pipelines and ducting. Among the different varieties, Dog Bone / Belt Type Expansion Joints are gaining popularity for their flexibility, cost-effectiveness, and efficiency.

In this comprehensive guide, we’ll explore what Dog Bone Expansion Joints are, how they work, their advantages, applications, materials, and why industries across the world rely on them.

What Are Dog Bone / Belt Type Expansion Joints?

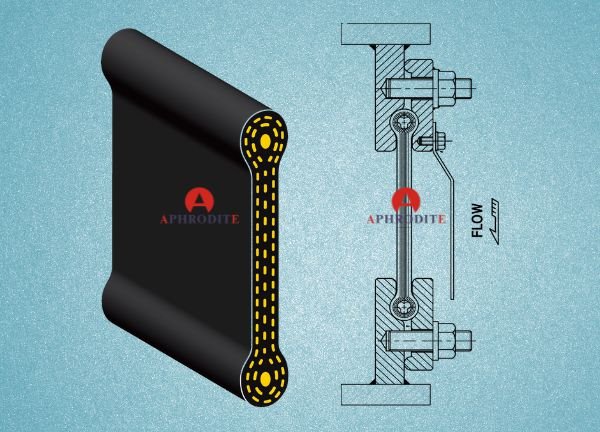

Dog Bone Expansion Joints, also known as Belt Type Expansion Joints, are flexible connectors used in pipelines and ducting systems. They are specifically designed to absorb:

Axial movement (expansion/contraction along the pipeline axis)

Lateral movement (side-to-side displacement)

Angular deflection (bending or misalignment)

Vibrations and shocks from rotating equipment

The term “Dog Bone” comes from the unique shape of the reinforcement structure, resembling a dog bone. This design provides the Joints with superior flexibility and durability.

These Joints are typically manufactured from reinforced elastomers such as rubber, neoprene, EPDM, Viton, or fabric composites. Their lightweight yet strong construction makes them an excellent choice for low to medium-pressure applications, especially where vibration absorption and movement compensation are critical.

Why Are Dog Bone Expansion Joints Important?

In industrial systems, pipelines and ducts are exposed to temperature variations, pressure changes, and continuous vibrations. Without flexible joints, this stress would cause cracks, leaks, or complete failure.

Dog Bone Joints play a vital role in:

- Protecting pipelines and ducting from thermal expansion and contraction

- Reducing mechanical vibrations and noise

- Allowing misalignment compensation during installation

- Increasing the lifespan of equipment like blowers, turbines, and fans

- Preventing costly shutdowns and downtime

In short, they ensure operational efficiency, safety, and reliability.

Key Features of Dog Bone / Belt Type Expansion Joints

High Flexibility – Capable of handling multiple movements (axial, lateral, angular).

Lightweight Design – Easy to install and replace compared to metallic bellows.

Shock Absorption – Excellent at dampening vibrations from mechanical equipment.

Weather & Corrosion Resistance – Suitable for harsh industrial environments.

Cost-Effective Solution – Economical compared to metallic alternatives.

Customizable Sizes – Available in standard and custom-built dimensions.

How Do Dog Bone Expansion Joints Work?

When a pipeline or duct system undergoes temperature fluctuations or mechanical movement, the rigid structure tends to expand, contract, or vibrate. A fixed connection would fail under these conditions.

The Dog Bone Expansion Joints act as a flexible buffer:

The belt-shaped body absorbs expansion and misalignment.

The reinforcement layer provides tensile strength.

The dog bone ends ensure a secure and leak-proof connection.

This design ensures that the stress is distributed evenly, preventing cracks and damages while maintaining system efficiency.

Materials Used in Manufacturing

The performance of expansion Joints depends on the materials used. Common materials for Dog Bone Expansion Joints include:

Natural Rubber – Good for low-temperature and general applications.

Neoprene – Excellent oil, ozone, and weather resistance.

EPDM (Ethylene Propylene Diene Monomer) – Ideal for hot air, steam, and chemical resistance.

Viton – Handles high temperatures and aggressive chemicals.

Fabric Reinforcements (Kevlar, Nylon, Fiberglass, Polyester) – Enhance tensile strength and durability.

Advantages of Dog Bone / Belt Type Expansion Joints

- Cost Savings – Lower initial investment compared to metallic expansion joints.

- Long Service Life – With proper material selection, they last for years.

- Noise & Vibration Reduction – Creates a safer and quieter working environment.

- Corrosion Resistance – Suitable for chemical and moisture-laden systems.

- Easy Installation & Maintenance – Reduces downtime and labor costs.

- Versatility – Suitable for multiple industries including power, cement, steel, HVAC, and marine.

Applications of Dog Bone Expansion Joints

Dog Bone Expansion Joints are widely used in industries where vibration absorption and flexibility are essential:

- Power Plants

- Steel Plants

- Cement Industry

- Chemical & Petrochemical Plants

- HVAC & Ventilation Systems

- Marine & Offshore Applications